Product Introduction

Spray drying is the most widely used process in liquid forming and drying industries. It is most suitable for producing powder and granular solid products from solutions, suspensions and paste liquid raw materials. Therefore, spray drying is an ideal process when the particle size distribution, residual moisture content, bulk density, and shape of finished products must meet the precise standards.

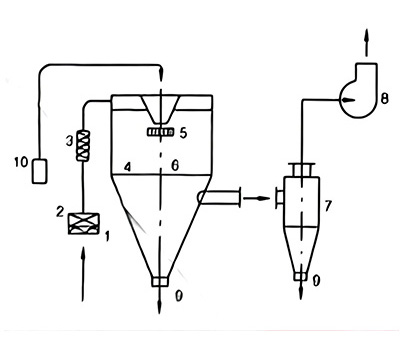

Working Principle

The air is filtered and heated before entering the air distributor at the top of the dryer. It then passes through the high-speed centrifugal atomizer on the top of the tower, which rotates to spray the liquid into extremely fine fog-like droplets. These droplets can be dried into finished products in a very short time when in contact with the parallel flow of hot air. The finished product is continuously output from the bottom of the drying tower and cyclone separator, and the exhaust gas is discharged by the fan.

- Air Filter

- Supply Fan

- Heater

- Hot Air Distributor

- Centrifugal Atomizer

- Drying Tower

- Dust Collector

- Induced Draft Fan

- Material Collection Device

- Feed Pump

Applicable Materials

1

Chemical IndustrySodium fluoride, potassium salts, alkaline dyestuffs and pigments, dyestuff intermediates, compound fertilizers, formic acid, silicic acid, catalysts, sulfuric acid agents, amino acids, white carbon black and so on.

2

Plastic & ResinsAcrylonitrile-butadiene (AB), acrylonitrile-butadiene-styrene (ABS) emulsion, urea-formaldehyde resin, phenolic resin, urea-formaldehyde resin, formaldehyde resin, polyethylene, polychloroprene and others.

3

Food IndustryFat-filled milk powder, protein powder, cocoa milk powder, milk powder substitutes, egg white (yolk).

4

Food & Plant DerivativesOats, chicken essence, coffee powder, instant tea powder, seasonings, meat protein, soybean protein, peanut protein, hydrolysates and etc.

5

Sugar & Related ProductsCorn syrup, corn starch, glucose, pectin, maltose, potassium sorbate and etc.

6

Ceramic MaterialsAluminum oxide, ceramic tile raw materials, magnesium oxide, talcum powder and so on.

Technical Specifications

| Model Project/Parameters | 5 | 25 | 50 | 150 | 200-2000 |

| Inlet temperature | 140-350 self-control | ||||

| Outlet temperature | 80-90 | ||||

| Water maximum evaporation rate (kg/h) | 5 | 25 | 50 | 150 | 200-2000 |

| Centrifugal atomizer drive form | compressed air drive | mechanical transmission | |||

| Maximum rotational speed(r.p.m) | 25000 | 18000 | 18000 | 15000 | 8000-15000 |

| Spray disc diameter(mm) | 50 | 120 | 120 | 150 | 180-240 |

| Heat source | electricity | steam+electricity | steam + electricity, fuel oil, gas, hot blast stove | ||

| Maximum power of electric heating(kw) | 9 | 36 | 72 | 99 | |

| Overall dimensions(L×W×H)(m) | 1.8×0.93×22 | 3×2.7×4.26 | 3.5×3.5×4.8 | 5.5×4×7 | determine according to the actual situation |

| Dry powder recycling(%) | ≥95 | ||||

Note: The amount of moisture and greasiness is related to the characteristics of the material and the inlet and outlet temperatures. When the export temperature is 90 ℃, the moisture recovery curve is shown in the upper circle (for selection reference). As the product is continuously updated, relevant parameters may change without prior notice.