Product Introduction

This machine adopts a fully enclosed structure, all components are made of stainless steel, and is equipped with a three-stage purification device. The filtered air meets the 100,000-class cleanliness requirement. Both the cylinder body and the top are equipped with cold wall devices to keep the wall temperature below 80℃, and the drying tower is equipped with an air brush tower cleaning device. After being dried by this machine, the traditional Chinese medicine extract powder will not have coking and deterioration phenomena, the powder collection rate is greatly increased (more than 95%), and there will be no medicine mixing phenomenon or wall sticking phenomenon.

Working Principle

The high-speed centrifugal spray device for traditional Chinese medicine extract is an application of centrifugal spray drying technology in the drying of specific materials. It is also a drying device that uses a high-speed centrifugal atomizer to disperse the material into mist droplets, which fully contact with hot air to achieve instant drying and form powdery finished products.

Characteristics

- The tower body is equipped with a cold air jacket

- The tower body is equipped with an automatic rapping device

- The tower body and pipelines are equipped with quick-opening cleaning holes and sewage discharge holes

- An automatically controlled constant temperature feeding tank can be equipped as an option

- Manual high-pressure tower washing random accessories can be equipped as an option

- Parts in contact with materials are made of stainless steel (or fully made of stainless steel)

- Material collection adopts a two-stage cyclone dust removal device, or a first-stage cyclone dust collector and a wet dust collector

- The inlet air temperature can be automatically and continuously controlled

- An air sweeping device can be equipped as an option

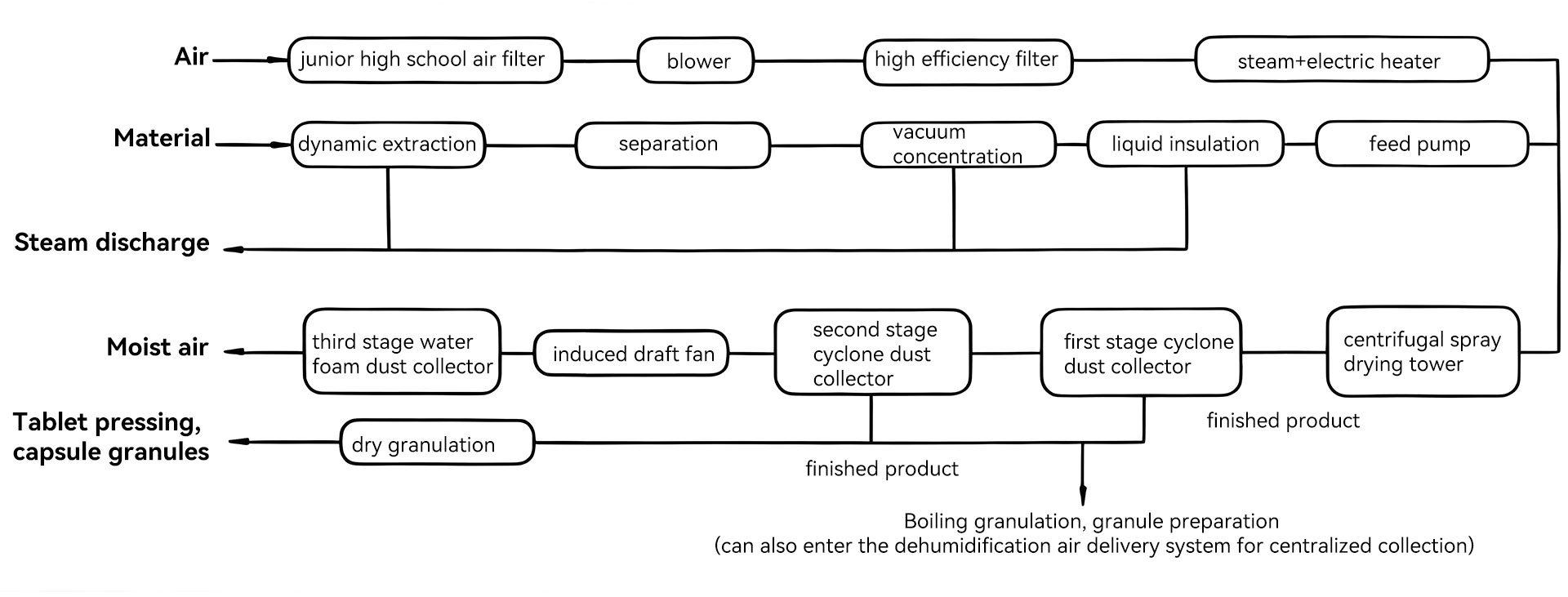

Flowchart

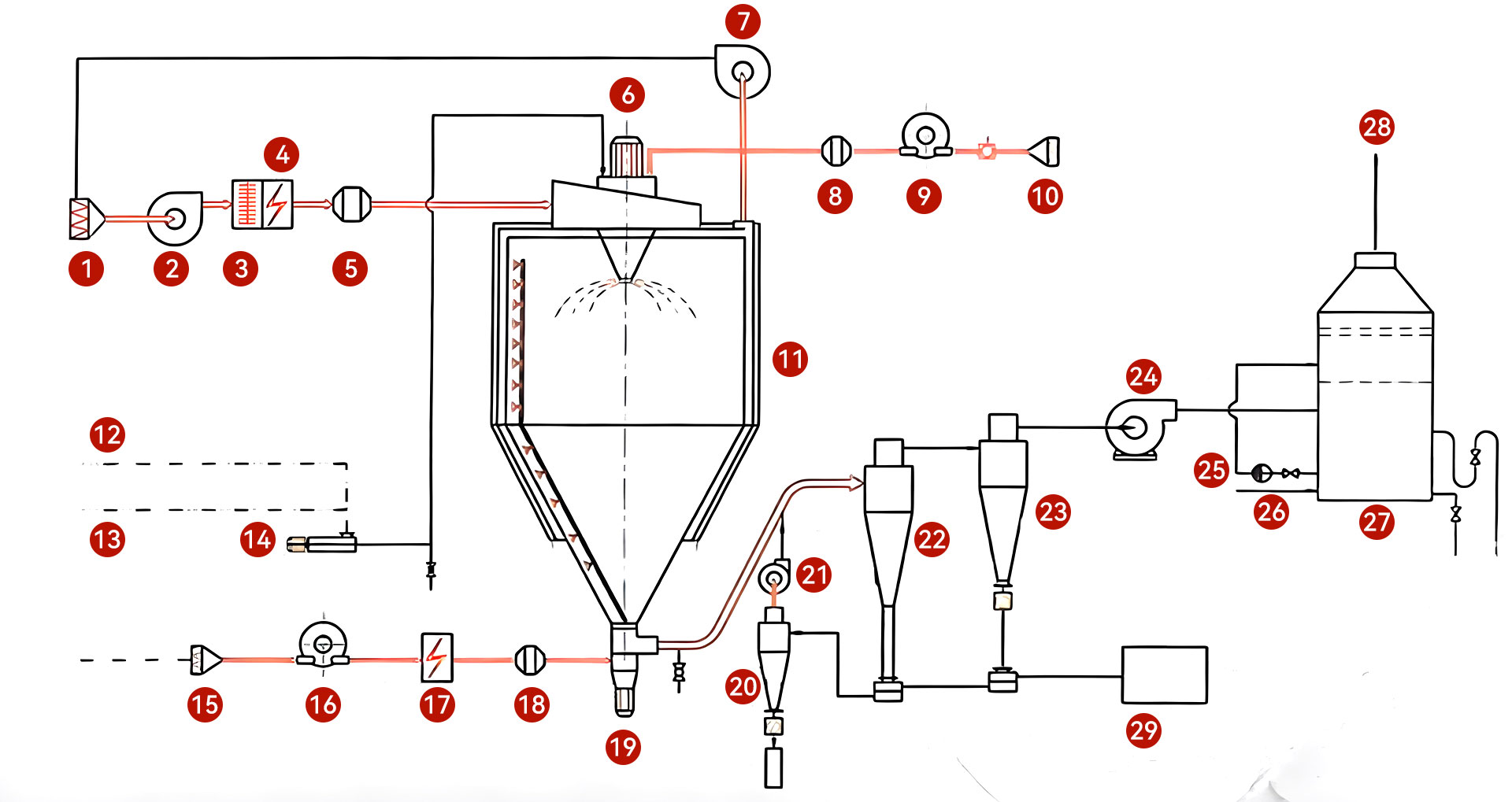

Installation Diagram

- primary / medium efficiency filtration

- blower

- steam heating

- electric heating

- high efficiency filter

- nebulizer

- cold air jacket fan

- high efficiency filter

- air pump

- primary / medium efficiency filtration

- tower body

- liquid material

- clear water

- feed pump

- filter hood

- roots blower

- electric heating

- high efficiency filter

- transmission system

- receiving whirlwind

- material receiving fan

- first level cyclone

- secondary cyclone

- exhaust fan

- circulating water pump

- tap water

- three stage water foam dust collector

- drain

- freezing dehumidifier

Technical Specifications

| Model | 50 | 100 | 150 | 200 | 300 | 500 | 1000 |

| Water evaporation rate | 50 | 100 | 150 | 200 | 300 | 500 | 1000 |

| Liquid processing capacity | 1600×8900 | 2000×11500 | 2400×13500 | 2800×14800 | 3200×15400 | 3800×1800 | 4600×22500 |

| Finished product output | 2~10 | ||||||

| Solid content of wet materials | 8.5 | 14 | 22 | 24 | 30 | 82 | 30 |

| Finished product water content | 140~350 | ||||||

| Electric power | <5 (up to 0.5) | ||||||

| Heat source | >97 | ||||||

| Product collection method and one-time collection efficiency | 75 | 120 | 150 | When the temperature is below 200: according to actual technology | |||

| Self-control instrument | 0.5+54 | 0.6+90 | 0.6+108 | ||||

| Self-control instrument | 100000 | 150000 | 200000 | 300000 | 400000 | 500000 | 1200000 |

| Inlet air temperature | ≥95 | ||||||

| Outlet air temperature | |||||||

Note: ★ The actual external dimensions can be determined according to the customer's actual situation, and the above dimensions are for reference only. The above evaporation rate is the maximum evaporation rate.